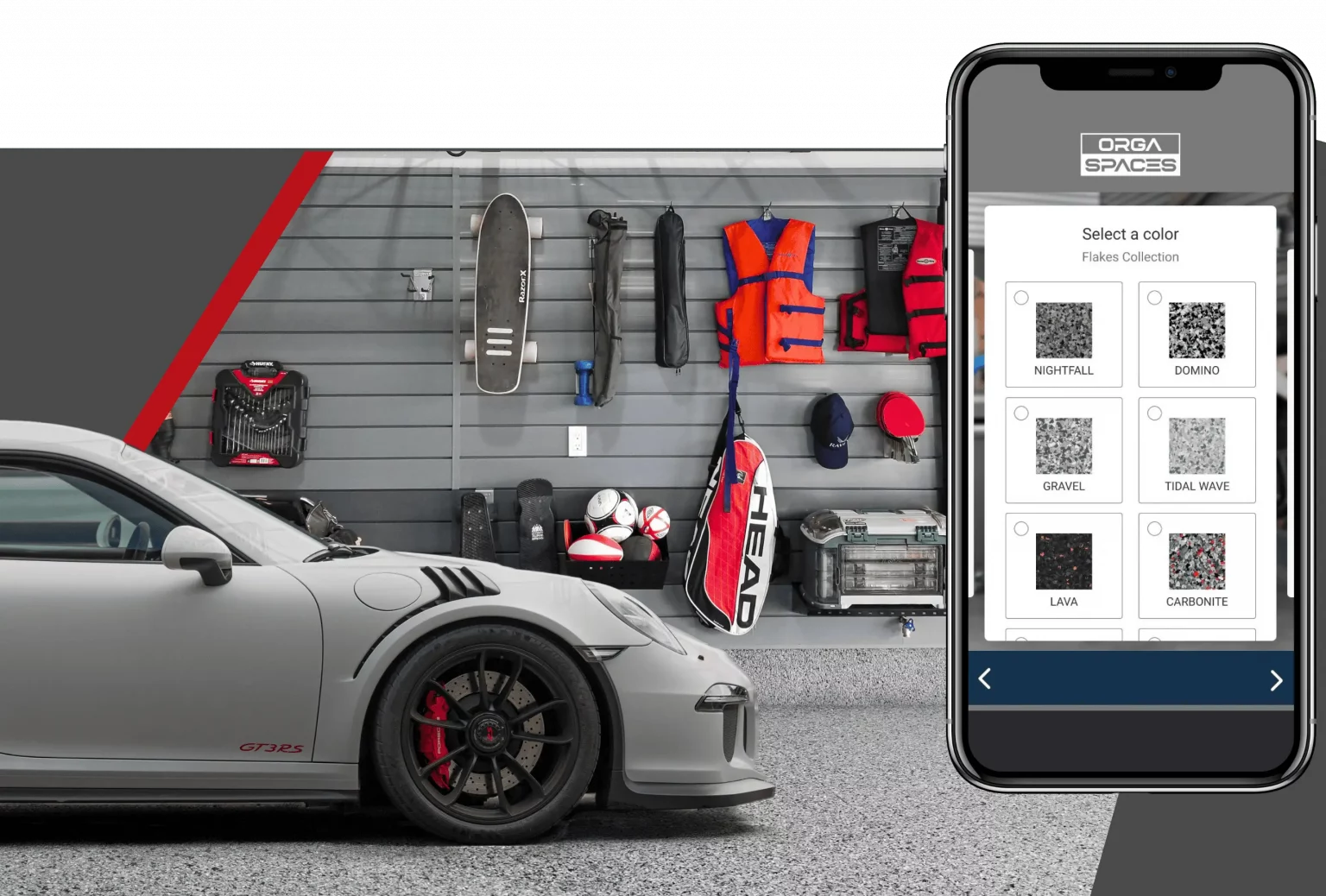

garage open flooring flakes system 4

Durable, stain resistant, and built to last for decades with professional garage floor epoxy and polyaspartic coatings.

Garage Flooring Quote Form

By submitting this form, you consent to receive SMS messages from our company. (unsubscribe anytime)

Transform your Dallas garage with our garage floor coating system. Our polyaspartic garage flooring outperforms traditional epoxy floors with superior durability, slip resistance, chemical resistance, and UV stability for a long-lasting finish that keeps your garage looking amazing year after year.

Faster than epoxy garage floors that take up to 7 days to cure. Our polyaspartic floor coating is ready the next day so you can use your garage quickly.

Resistant to salt, oil, gas, and grease. Chemicals can be cleaned up without staining or damaging your garage floor coating.

Epoxy flooring yellow in the Texas sun. Polyaspartic coatings keep your garage floor bright and like new.

Easy maintenance with a stain resistant garage floor. Spills wipe away fast with no permanent marks.

Epoxy garage floor coatings have been around for years, polyaspartic coatings are the modern upgrade: faster curing, longer-lasting, more UV resistant, and tougher against Texas heat and heavy use.

Polyaspartic cures in one day. Epoxy garage coatings require 2 to 3 days.

No yellowing or fading like epoxy garage floors.

More impact resistant, less likely to crack than epoxy floor coatings.

Polyaspartic garage floor coatings provide superior grip and traction.

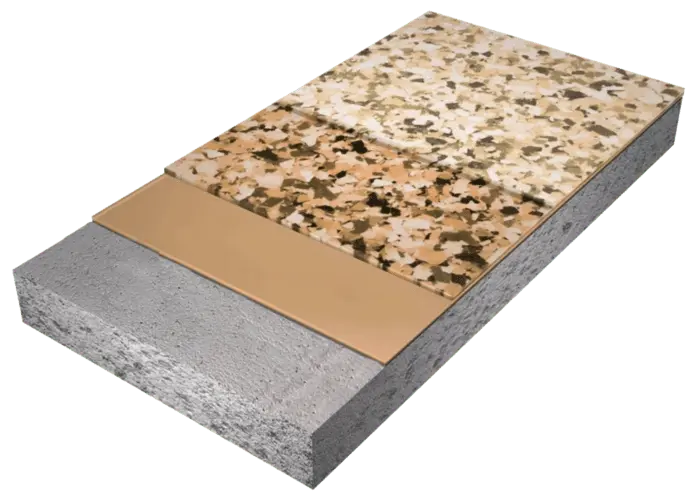

Top Coat

Polyaspartic sealer

Flakes Layer

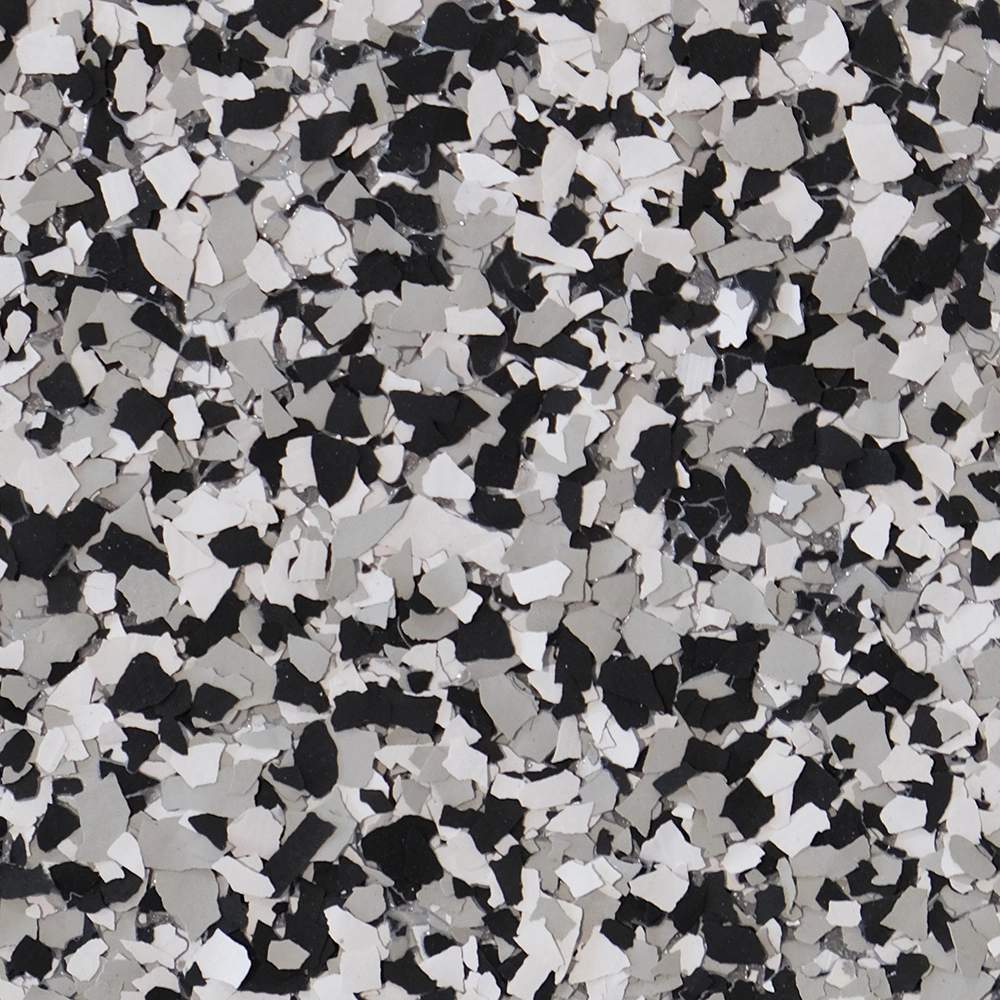

12 colors to choose from

Base Coat

Polyurea layer

Concrete

Diamond grinding and surface repair.

Our polyurea and polyaspartic system transforms ordinary concrete into a surface that’s strong, seamless, and built to last. Engineered to resist damage from wear, impact, and temperature changes, it keeps your floor looking flawless year after year. With its quick installation and premium finish, it’s the perfect balance of toughness and style for any garage.

Preparation

Preparation Concrete Repair

Concrete Repair Priming

Priming Flaking

Flaking Topcoat

TopcoatFirst, we diamond grind in all areas and open cracks with a V-cut blade, resulting in a smooth surface, ready for repairs and future coating. Dust is minimized with HEPA vacuums.

Filling cracks, pits, and imperfections with fast curing crack fillers. Then grinded again, making the entire surface ready for coating.

The 1st coat is a Polyurea primer coat. Polyurea forms an impermeable barrier over the concrete, preventing water from seeping through the surface.

The second layer is a Flake chip broadcast of a color of your choosing, providing texture and color to your floor.

The final layer is a clear Polyaspartic sealer, UV resistant and built to last for decades. Unlike epoxy which requires longer cure time, the polyaspartic flakes system is ready for use the next day!

garage open flooring flakes system 4

nightfall flakes garage flowers outside 8

orgaspaces warranty card flooring 12

tape do not enter orgaspaces 16

polyurea floor and wall storage 20

epoxy floor coating 24

Cabinfever flakes detail 28

nightfall flakes garage 32

carbonite floor coating 36

Ready for the best garage floor coating in Dallas? Contact us, professional epoxy floor contractors, to install a premium polyaspartic epoxy garage floor coating today.